Logistics Automation Engineering

Logistics Automation Engineering

Creating a safe and efficient warehouse environment with specialized automation technology of Nongshim engineering.

Logistics business environments

Local area/real-time logistics

Multi-product logistics

Miniaturized warehouse

Population decrease/

labor costs increase

Logistics competition and

cost incresae

Automated warehouse

Personalized, customized logistics

IOT/Big data

Information warehouse

Rapid change to multi-product & miniaturization logistics service!

Increasing needs for high efficient automated smart warehouse!

Synergy effect of specialized business fields of Nongshim Engineering

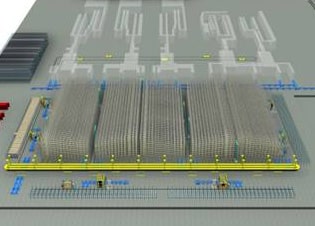

MDPS (Multi Deep Pallet System)

- Shuttle rack type of automated warehouse system

- Securing a majority of cells in small place

- Maximizing space utilization/ flexible operation

Smart In-house Logistic System

- Logistics automation for the entire range of receiving and production

- Safe and efficient unmanned system

- Optimal response to high wage and low labor environment

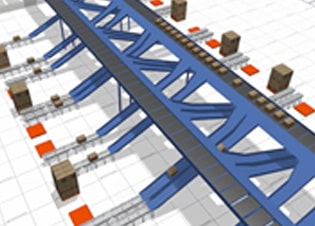

Compact Sorting System

- Fast and accurate lot delivery system

- Support for multi-products/small delivery/flexible operation

- Tracking system with brand new information system

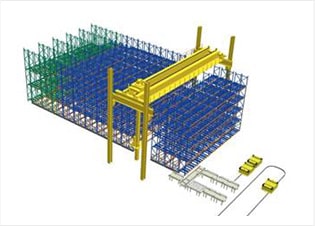

Flow Rack Automatic

Warehosing & Forwarding System

- Combination of flow rack and stacker crane

- Enforcement of first-in-first-out function

- Realization of and computerization

Mibile Rack Automatic

Incoming/Outgoing

- Patented technology integration

- Automated Receiving-Storage- Shipping system

- High storage efficiency

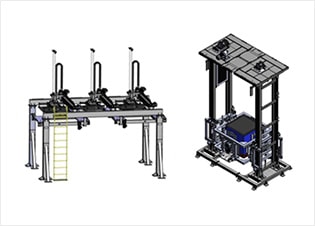

Slip Sheet Insert System

- Multi function system

(Pallet & Slit sheet) - Automated system

(Slip sheet applied) - Excellent logistics cost savings

Synergy effect with specialized business field of Nongshim Engineering

Construction of various

industrial facilities and

logistics centers

Smart energy saving

technology

Optimized

IT solution

Reliable O & M Service

Quick

responce

Preventive

maintenance

Operation failure

minimization

Lifespan

expansion

Performance

improvement

Technology

support

Quick

responce

Preventive

maintenance

Operation failure

minimization

Lifespan

expansion

Performance

improvement

Technology

support